Region

India

- Region India

- Industry Prosthetics

- Challenges

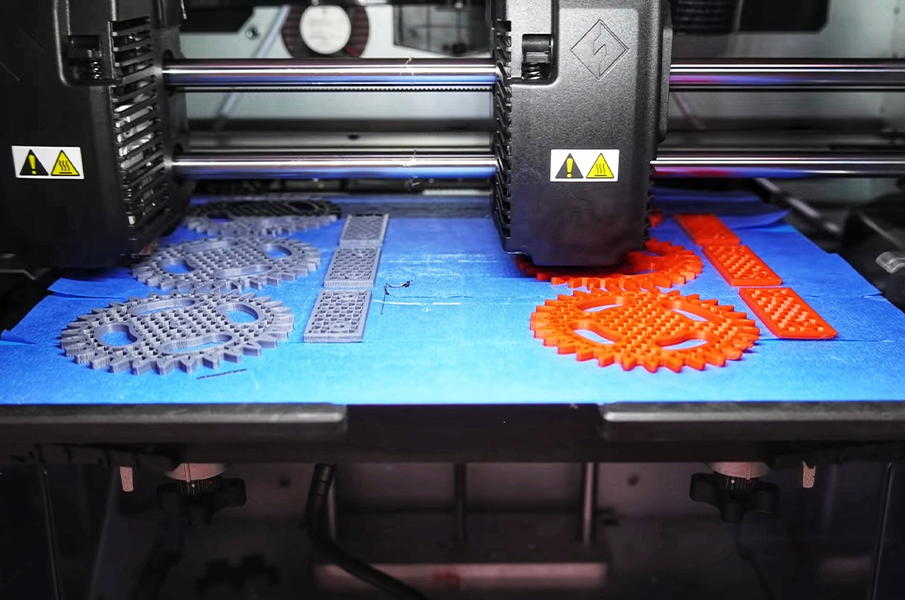

- Huge investments is required for starts-ups to commercialize their innovations & designs using conventional manufacturing process

- Product adoption & market potential will make new projects commercially unviable. Parts printed using conventional 3D Printers was not fulfilling the quality & certification requirements.

- Solutions

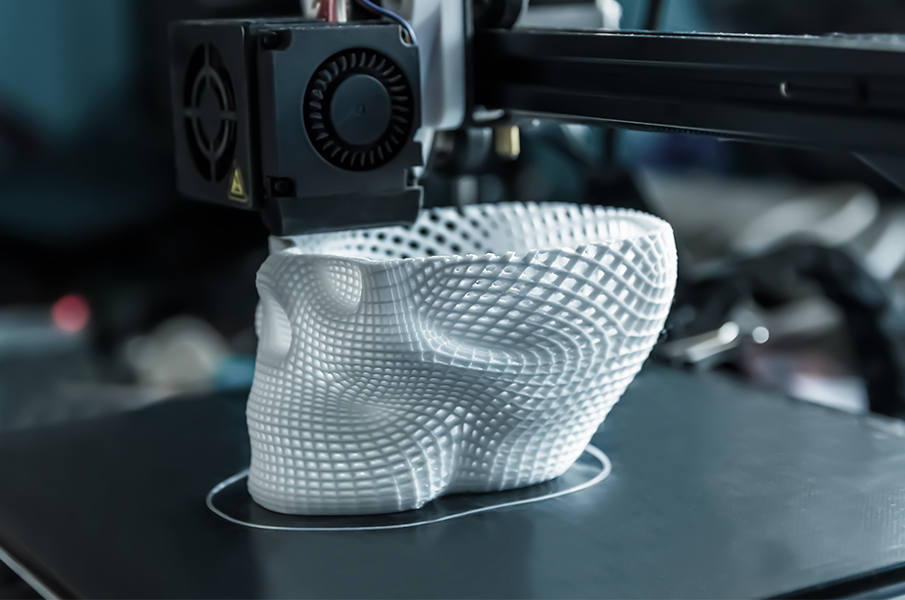

- Redington offered its production services during design, development, testing & certification of India’s first indigenously developed bionic hand & helped MakersHive to commercialize the product. Considering the production volume & Personalisation requirement, MakersHive opted for HP MJF technology for its manufacturing & chose Redington as its manufacturing partner.

- Outcome

- On-demand digital manufacturing services from Redington not only helped to bring out innovations to reality, but also helped to personalize their products as per the requirement of its patients

- At low investment in tooling, MakersHive was able to launch & manufacture India’s first myoelectric bionic hand & offer products at almost 30% cost of imported bionic hands

Enquiry